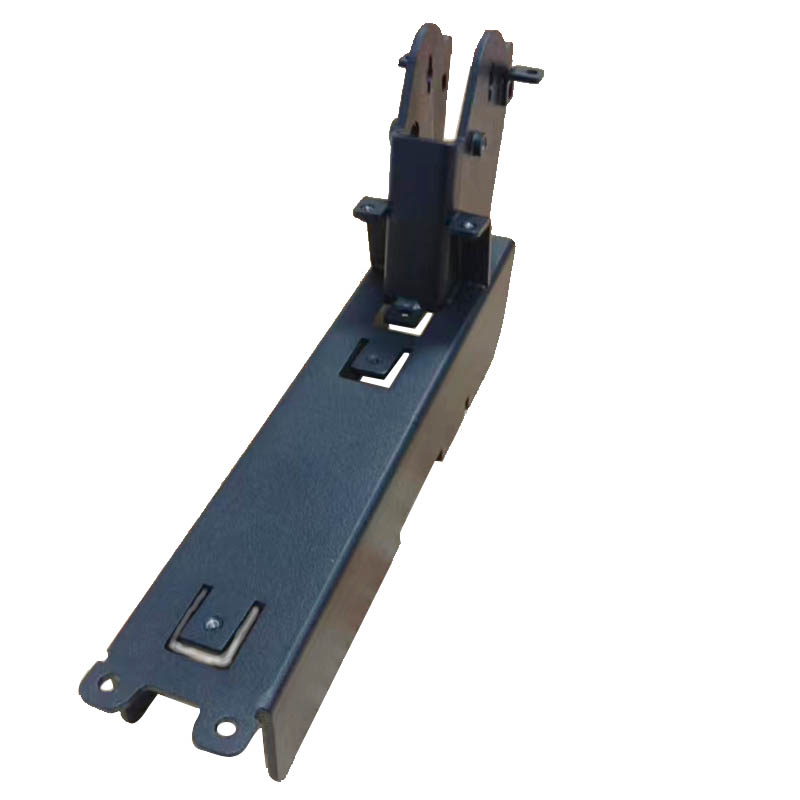

metal stamping Parts

Metal Stamping Company

Our engineering design team participates in the entire process of the customer's mold design and development, assisting the customer to quickly confirm and complete the design structure drawing, from the careful selection of materials in the early stage, to the production of hardware and plastic molds and proofing in the later stage, and then to the production process. It can accurately control the detailed costs of the production process and achieve a higher cost performance on the basis of ensuring product quality. Provide comprehensive process solutions for stamping and injection molding accessories

SING OI committed to providing customers with comprehensive process solutions for metal stamping accessories and plastic injection molding, we provide drawings and samples, custom processing, process quality first, integrated services to win with quality, and the engineering team meets every customer need.

In terms of services, we implement digital management of customers and follow up one-on-one quality control throughout the process to ensure that customers’ quality needs are communicated in a timely manner and receive more considerate and secure services. In terms of technology, we promote process engineers to optimize the production process and reduce the loss factors of defective products. , strengthen quality control, reduce production costs and customer transaction costs, and achieve a win-win situation. We are attentive and our customers can rest assured.

From the handling of all details of total quality management to the participation of all employees in quality management work, all departments of the company work closely with each other. The active participation and cooperation of all employees enables the quality management team to carry out its work better and serve customers in an all-round way.

Environmental protection is the responsibility of the enterprise. The raw materials required for the company's surface treatment process are all used in compliance with national standards, and suppliers are regularly audited and inspected. The sludge and biogas generated during the production wastewater treatment process are rationally developed and recycled to improve Improved wastewater reuse rate and reduced water consumption. While fulfilling its environmental responsibilities, the company also ensures the interests of its customers.

PREVIOUS:metal stamping companies NEXT:stainless steel stampings suppliers

Categories

Blog

Contact Us

Contact: plastic injection molding Company

Phone: +86 181 6575 9852

Tel: +86 755-27164277

E-mail: windward@seaiint.com

Add: Northwest of Huihao Industrial Park, No. 1, Chuangwei Road, Guangming District, Shenzhen